Contacts

Santa Fe, NM 87507

Have a Question?

BMW Walnut Blasting

BMW Walnut Blasting Service

Walnut Blasting is a factory recommended service for BMW and MINI owners every 30,000 miles.

You may think your BMW is in need of a Tune Up, but it could be more than that.

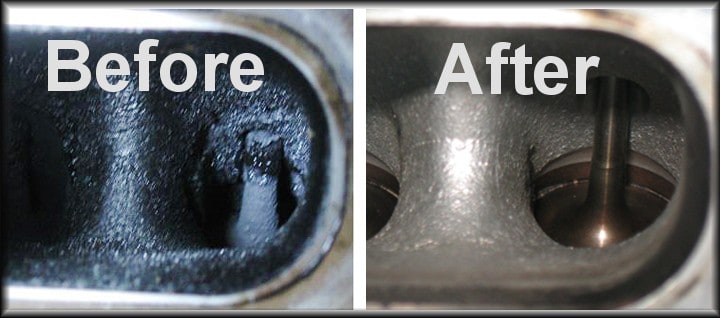

As your BMW or Mini approaches 30,000 miles, and certainly at the 60,000 mileage mark, your BMW* will most likely experience carbon build-up on the Intake Valves of your direct injection engine*. This build-up affects the way air enters the combustion chamber, causing many symptoms, which can include misfiring, rough running, hard starting, and poor fuel economy.

If that were not enough, the likelihood of a burnt valve is greatly increased, and will cost much more to repair in the long run.

BMW Intake Valve Carbon Cleaning

Causes of Direct Injection Carbon Build-Up

In the ongoing effort by car manufacturers to improve performance, and mileage, they have made some advances to the design of the fuel injection, and emission control systems used in many of todays modern engines.

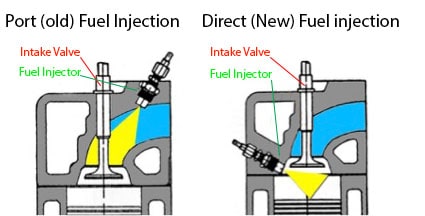

One major modification is that they have moved (changed the location) of the fuel injector from the intake

manifold, to directly in the cylinder (combustion chamber). This design is referred to as a “direct injected engine” and has many performance gains.

Previously, the fuel injectors used to be in the intake manifold, close to the intake valves of the engine. With this design the injector would spray the fuel past the valve and it would act like a cleaning agent and clean or prevent oil and carbon deposits from accumulating on the intake valves.

Why is there carbon and oil on the intake valve in the first place?

In addition to the intake valves becoming coated with solid carbon deposits, with the continued evolution of the emissions systems, one of the techniques is to divert the crankcase fumes, generally referred to as “Blow-By”* and re-direct them into the intake manifold to allow them to be mixed as part of the combustion process, therefore ensuring the fumes don’t vent to atmosphere. They then go thru the catalytic convertors to get cleaned before exiting the exhaust system and entering the atmosphere. The combination of these two designs has caused the intake valves to now become a collector of oil and carbon deposits.

Breathing Life Back Into Your BMW or Mini Cooper

The Process of Walnut Blasting

Walnut blasting is a process by which we clean the intake manifold and valves of your BMW (or Mini’s) engine with a high pressure air blast of finely crushed walnut shells (a biodegradable abrasive ground to between 0.018 and 0.03 inch!).

Utilizing special equipment specifically developed for this purpose, at the same time the valves are being blasted, a custom vacuum adapter suctions the broken down carbon and walnut residue from the manifold.

The end result being the carbon buildup is gone and the wear and tear has been eliminated, extending the life of your engine and now you can expect:

- Better throttle response

- Smooth idle engine

- Improved fuel economy

- Increased horsepower

There is an interesting article from Consumer Reports about Walnut Blasting that you can read here …

- What is Blow-By?

During combustion, high pressure on the top side of the piston pushes combustion gasses, as well as droplets of oil and fuel, past the piston rings and into the crankcase. This mixture is known as “blow-by.”

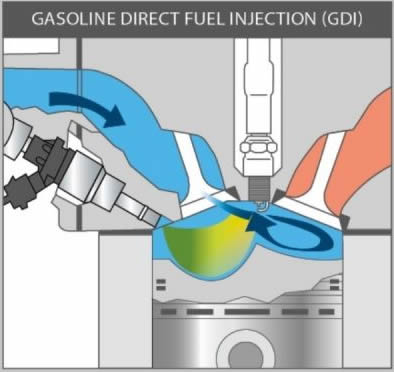

- What is a GDI Engine?

Gasoline direct injection (GDI), is a mixture formation system for internal combustion engines that run on gasoline, where fuel is injected into the combustion chamber. This is distinct from manifold fuel injection systems, which inject fuel into the intake manifold.

The use of GDI can help increase engine efficiency and specific power output as well as reduce exhaust emissions

- Which BMW’s use GDI?

The most common are direct injection turbo charger engines.

Mini – N14 Engine – R55, R56, R57,

Mini – N18 Engine – R56 LCI, R57 LCI, R60

BMW N54 Engine – E60, E60 LCI, E61 LCI, E90, E92, E93, F02

BMW N55 Engine – E70, E70 LCI, E82, E84, E90, E93 LCI, F02 LCI, F10, F15, F16, F25, F26, F30, F33

BMW M57 – Diesel Engine – E70D & E90D